Treatment Agent For Iron & Steel (Spraying )

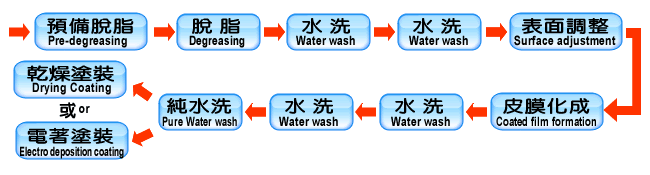

Treatment procedure -> The coated film formation of zinc phosphate

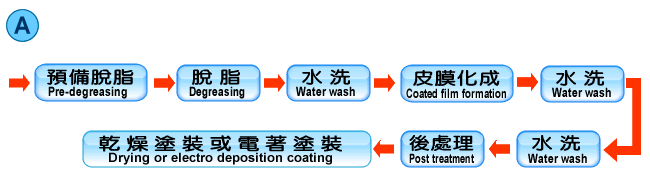

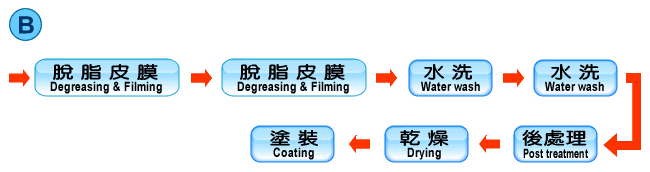

Treatment procedure -> The coated film formation of ferric phosphate

Degreasing agent

|

CF NO.

|

Using method

|

Characteristic

|

||

|

|

Concentration(%)

|

Temperature(°C)

|

Time(min)

|

|

|

104

|

1~2

|

45~50 |

1.5~2.5

|

It is a degreasing and adding agent with spraying. |

|

104B

|

1~2

|

45~50 |

1.5~2.5

|

It is a degreasing and adding agent with spraying. |

|

130

|

2

|

45~50

|

1.5~2.5

|

Both general or galvanized iron and steel can be used. |

|

103A

|

2

|

45~50

|

1.5~2.5

|

Both general or galvanized iron and steel can be used. |

|

103H

|

2

|

45~50

|

1.5~2.5

|

It belongs to a non-phosphate type, and both general or galvanized iron and steel can be used. |

|

131

|

2

|

45~50

|

1.5~2.5

|

It belongs to a strong degreasing agent. |

|

132B

|

2

|

45~50

|

1.5~2.5

|

It belongs to a strong degreasing agent. |

|

137

|

2

|

25~50

|

1.5~2.5

|

It belongs to the type of normal temperature, and both general or galvanized iron and steel can be used. |

|

140

|

2

|

45~50

|

1.5~2.5

|

The agent can be used with surface adjustment |

Surface adjustment

|

CF NO.

|

Using method

|

Characteristic

|

||

|

|

Concentration(%)

|

Temperature(°C)

|

Time(min)

|

|

|

BK-3

|

0.2

|

Normal temperature |

0.5~1

|

It can increase the reaction of coated film for fine crystal. |

|

BK-3A

|

0.2

|

Normal temperature |

0.5~1

|

It can increase the reaction of coated film for fine crystal. |

|

BK-3B

|

0.5~1

|

Normal temperature

|

0.5~1

|

It can increase the reaction of coated film and restrain rusting. |

Filming agent

|

CF NO.

|

Using method

|

Characteristic

|

||

|

|

Concentration(%)

|

Temperature(°C)

|

Time(min)

|

|

|

407N

|

2.5

|

~50 |

1.5~3

|

It is a general zinc phosphate filming agent. |

|

407NA

|

2.5~4

|

~50 |

1.5~3

|

It is a general zinc phosphate filming agent. |

|

407NB

|

2.5~4

|

45~50

|

1.5~3

|

It is a general zinc phosphate filming agent. |

|

407S

|

4

|

45~50

|

1.5~3

|

It belongs to a series of zinc and manganese, and it has good corrosion resistance which is suitable for electro deposition coating. |

|

407SA

|

4~5

|

45~50

|

1.5~3

|

It belongs to a series of zinc and manganese, and it has good corrosion resistance which is suitable for electro deposition coating. |

|

457

|

2.5

|

35~45

|

1.5~3

|

It belongs to a thin film type and a series of zinc and calcium. It also has good corrosion resistance which is suitable for electro deposition coating. |

|

501S

|

4

|

45~50

|

1.5~3

|

It belongs to single liquid type with zinc phosphate coated film. |

|

5101

|

3.5

|

45~50

|

1.5~3

|

It is a zinc phosphate filming agent with quite thin film which is suitable for electro deposition coating. |

|

707S

|

2.5~5

|

45~50

|

2~3

|

It belongs to a series of ferric phosphate, both degreasing and coated film can be used. |

|

707

|

1~2

|

45~50

|

2~3

|

It belongs to a series of ferric phosphate which is suitable for cast iron. |

|

705

|

5~10

|

45~50

|

2~3

|

It belongs to a series of ferric phosphate which is suitable for everything. |

|

BFF-7

|

2~3

|

~50

Normal temperature~50 |

2~3

|

It belongs to a series of ferric phosphate and has good corrosion resistance. |

|

BFF-8NB

|

2~3

|

~50

Normal temperature~50 |

2~3

|

It belongs to a series of ferric phosphate and has good corrosion resistance. |

|

BFF-10

|

3~4

|

~50

Normal temperature~50 |

2~3

|

It belongs to a series of ferric phosphate and has good corrosion resistance. |

|

BFF-12M

|

2~3

|

~50

Normal temperature~50 |

2~3

|

It belongs to a series of ferric phosphate, both degreasing and coated film of iron and aluminum can be used. |